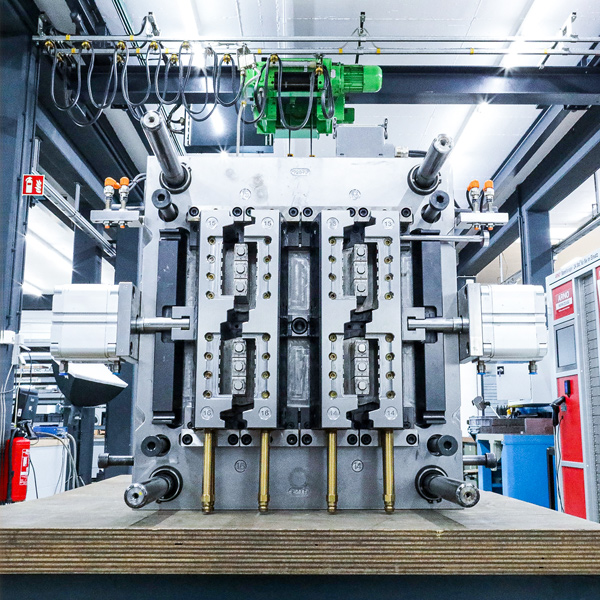

Mold Making: Quality with Passion

We use high-tech to create excellent production tools.

We produce high-quality tools for the large-scale production of precise plastic parts – including those that require an aesthetically pleasing feel and look.

Our specialties include:

-

single and multi-component tools

-

multi-cavity molds

-

stack tools

-

hot runner molds

-

boring tools

-

tools with pulsed cooling or conformal cooling

Quality means cost-effectiveness. And reliability ensures higher productivity. Our molds are characterized by the following features:

-

long service life

-

low maintenance requirements

-

user-friendly design and documentation

-

production reliability

-

short cycle times

-

low waste

In order to be able to realize customer wishes as quickly as possible, we focus on commitment and short decision-making paths within the company. This enables us to implement shape changes and shape optimizations quickly. Our customer-oriented project management is a competent contact partner in every processing phase.

Our mold making meets the highest quality standards: Innovative manufacturing and automation technology as well as air conditioning of the sensitive production areas are a matter of course. We have a high vertical range of manufacture and provide all manufacturing technologies relevant to mold making in-house.

Development and Construction

With our many years of know-how, we look forward to supporting you as a partner. When developing and building tools, we use the latest software and simulation applications. Our team of engineers and designers advises and accompanies you from the project’s conception to the finished product.